Hyundai Worldwide Global Navigation

- Go to Global Distributors page

- KR

-

Search

Editorials Innovation in Motion: The Story Behind Hyundai Motor Group’s 2-Stage Motor System

Please use Safari to download the files.

How Hyundai Motor Group’s advances in electrification are redefining performance and efficiency

Electric vehicles are transforming the way we move, but what defines a truly great EV experience? Customers today expect thrilling performance and efficiency – and Hyundai Motor Group’s advanced motor technology delivers exactly that.

Hyundai Motor’s IONIQ 5 N and Kia’s EV6 GT prove that EVs can engage drivers in ways we’ve not seen before, balancing this with exceptional every-day usability and refinement. The technology behind this blend of attributes, broadening the operating window of the Group’s EVs, is innovation in motion.

In this article, we’ll explore Hyundai Motor Group’s 2-Stage Motor System in detail, explaining how this award-winning technology delivers both supercar-level performance and exceptional energy efficiency – something that, up until now, has been considered unattainable.

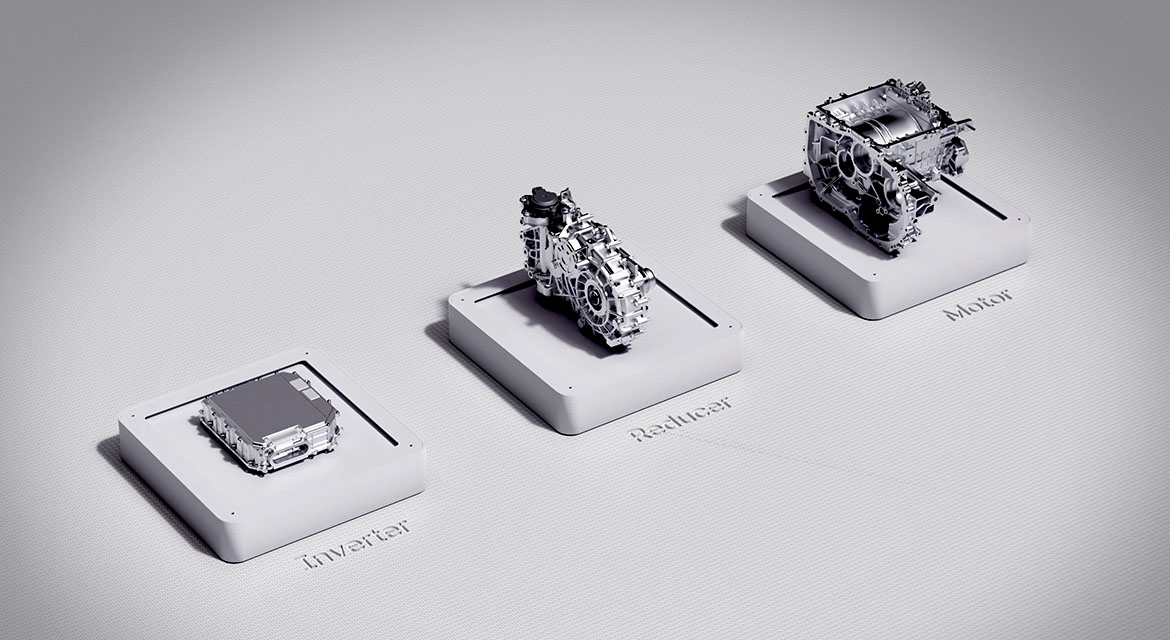

At the heart of this system are three essential components:

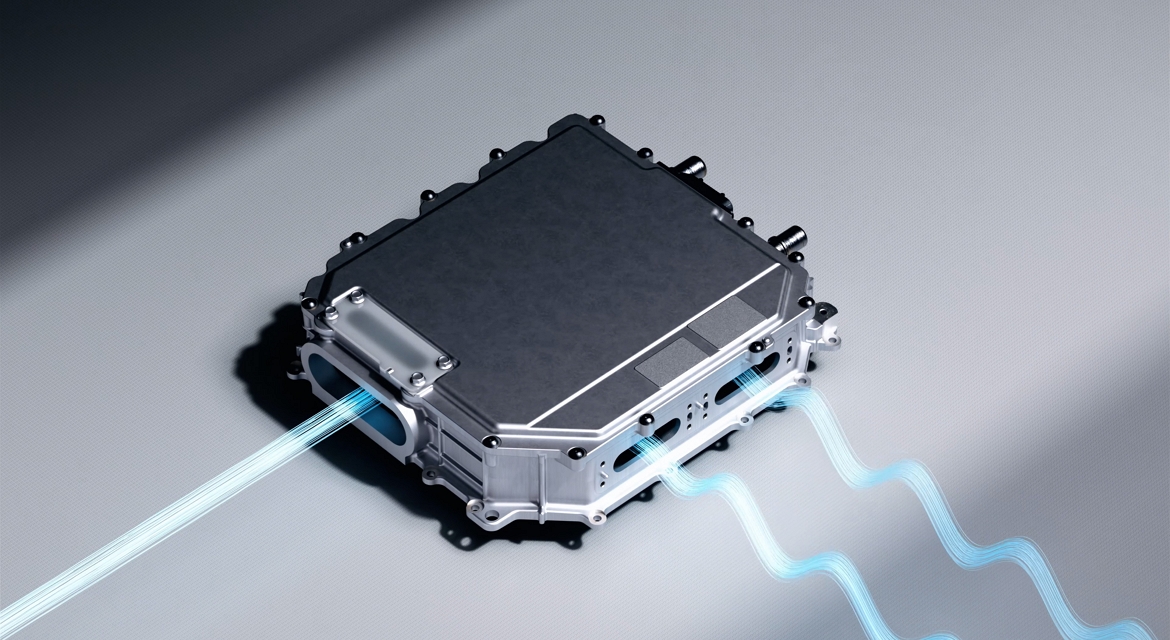

1. The inverter – converts DC power from the battery into AC power for the motor

2. The motor – generates rotational force

3. The reducer – transfers this force to the wheels

Expanding Voltage Utilization

An EV’s power output depends on the voltage and current the battery can deliver to the motor (or motors) via the inverter. Traditionally, increasing current resulted in heavier propulsion systems and greater heat management challenges. Motor systems optimized for high output in this way often compromise efficiency during everyday driving, but Hyundai Motor Group’s R&D innovations have overcome this challenge by rethinking the inverter.

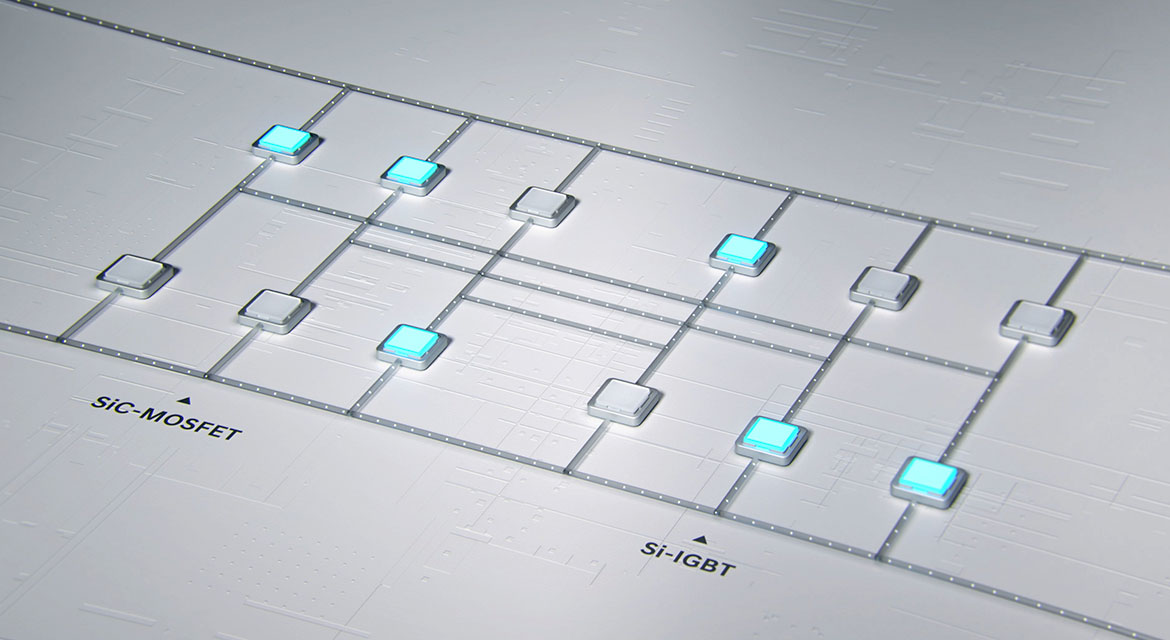

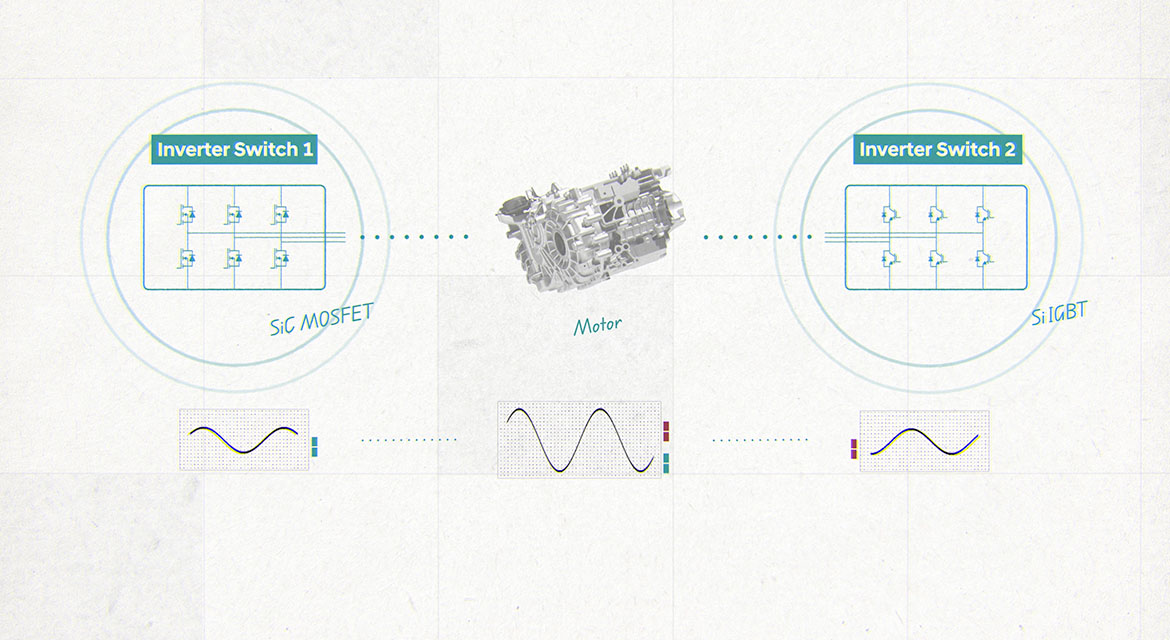

The 2-Stage Motor System features a dual inverter structure equipped with 12 semiconductor switches in a “6 plus 6” configuration, doubling the conventional count. One set of six switches uses silicon carbide (SiC) semiconductors for high efficiency, while the other set uses silicon (Si) semiconductors to support high-power conditions.

This configuration increases the voltage that can be supplied to the motor by up to 70 percent, enabling a higher power output without compromising efficiency.

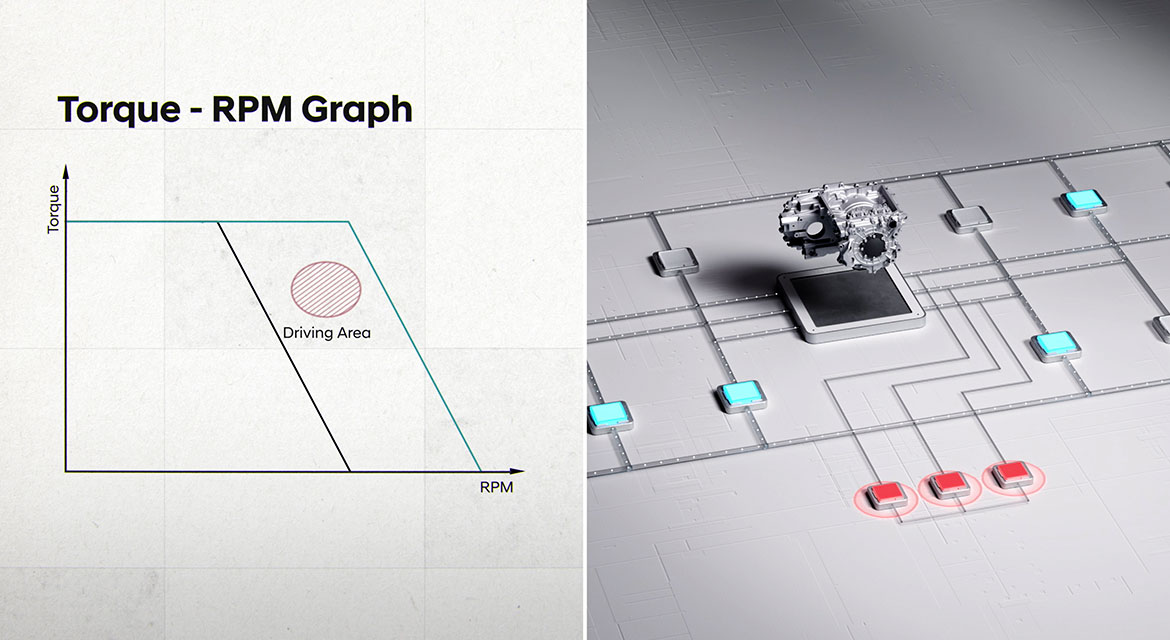

The system operates intelligently based on Hyundai Motor Group’s smart dual-mode control, split across the following conditions:

Advanced Control Architecture

Hyundai Motor Group developed proprietary control algorithms to ensure seamless transitions between these two modes.

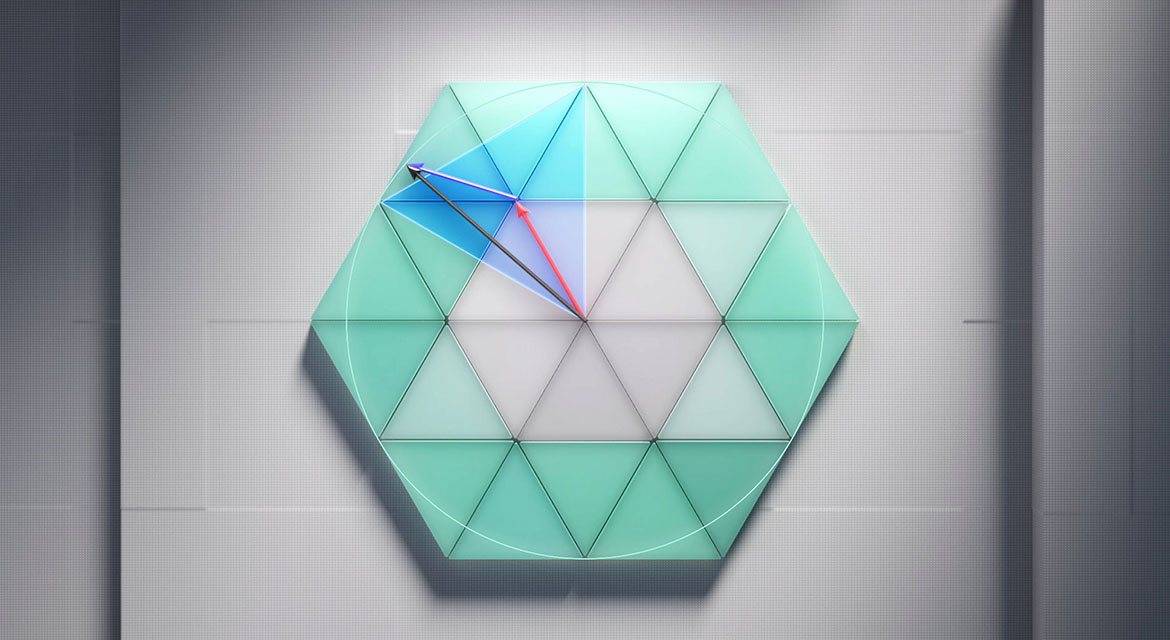

Doubling the number of switches was not just a hardware upgrade – it required a complete redesign of the control system. A conventional six-switch inverter operates in eight combinations, but with 12 switches, the combinations multiply eightfold, demanding far more precise coordination and control.

The proprietary algorithms manage this complexity, smoothing voltage transitions and delivering seamless, uninterrupted and powerful performance. The system uses a transfer switch to shift seamlessly between modes, ensuring strong power when accelerating and high efficiency during long-distance driving.

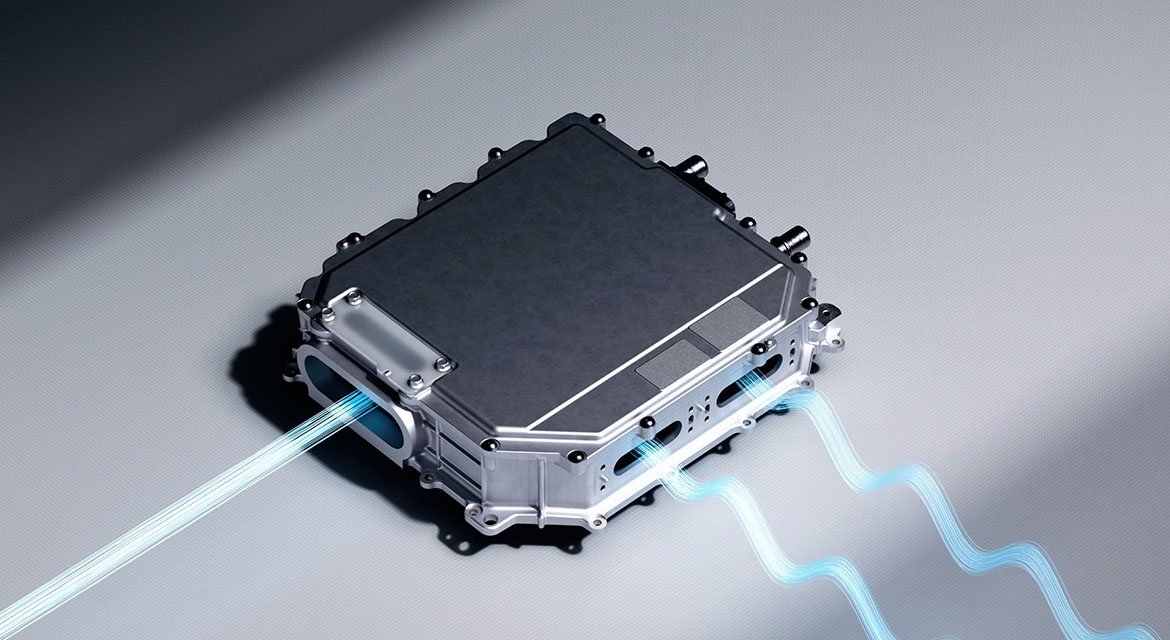

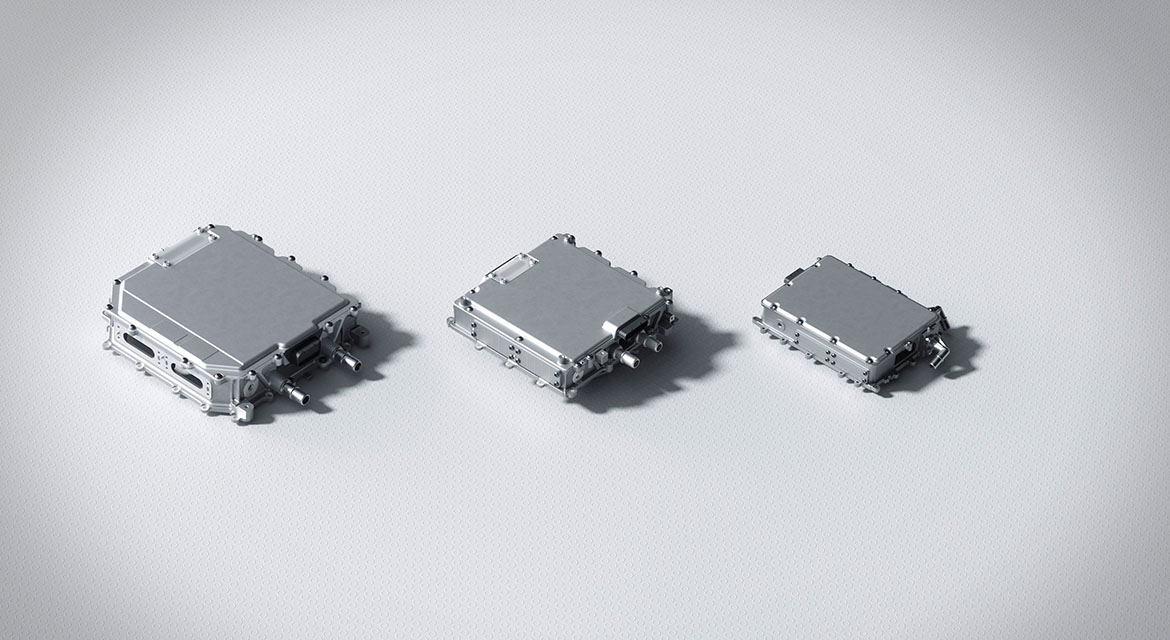

Compact and High-Performance Design

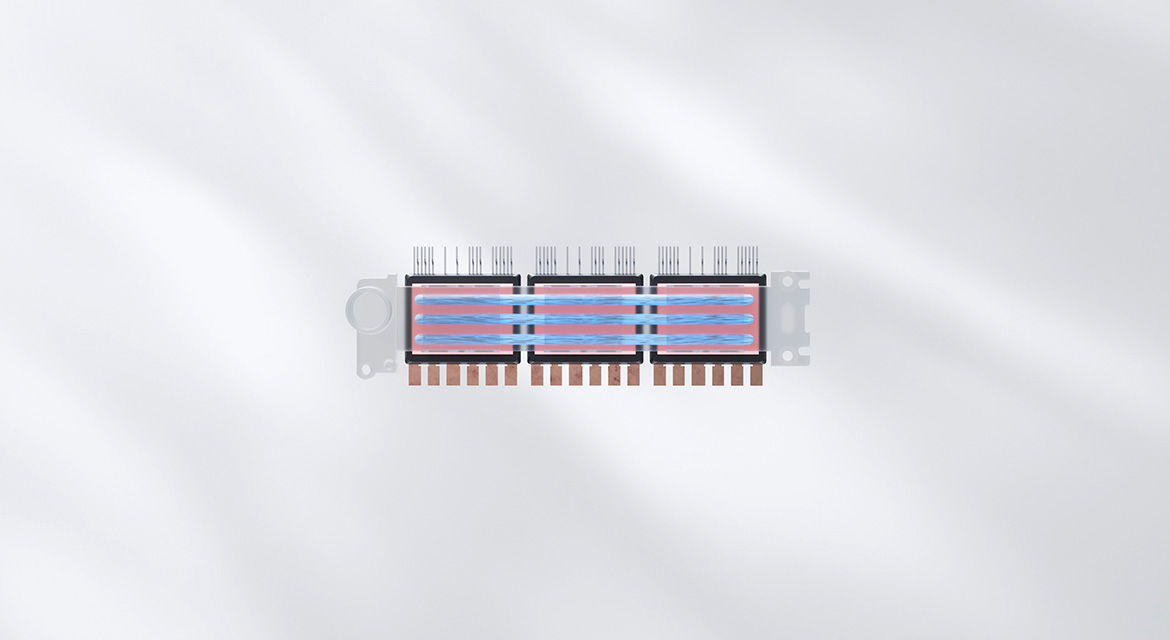

Despite the added complexity, the inverter remains compact thanks to Hyundai Motor Group’s in-house power module design. Each module houses the power semiconductor switches and provides packaging that ensures heat dissipation and electrical insulation.

To achieve a smaller, lighter inverter, Hyundai Motor Group integrated nine modules into three, reducing size and weight while maintaining durability. The cooling system was also enhanced with a double-sided setup, significantly improving heat dissipation. This enhancement allows for higher power density within a smaller package, enabling high output without increasing overall dimensions. These optimizations mean the 2-Stage Motor System delivers cutting-edge capability while remaining practical for mass production.

This 2-Stage Motor System is the only setup of its kind to achieve both high performance and efficiency – this technology represents a major leap forward in EV engineering, delivering thrilling driving experiences without compromising sustainability.

This innovation earned the Presidential Award at the 2024 Korea Technology Awards, the nation’s highest honor for technological excellence – underscoring Hyundai Motor Group’s leadership in EV innovation.

The 2-Stage Motor System is already powering high-performance EVs, such as the Hyundai IONIQ 5 N, IONIQ 6 N, IONIQ 9, and the all-new NEXO FCEV, as well as the Kia EV6 GT, EV9, and EV9 GT, setting a new benchmark for electric mobility worldwide.

Hyundai Motor Group aims to make advanced EV technology more accessible and transparent – helping customers appreciate the engineering that powers their driving experience. As electric mobility continues to evolve, innovations like this 2-Stage Motor System will remain central to delivering both excitement and efficiency, reinforcing the Group’s commitment to shaping a smarter, more sustainable future.

Sean Carson

sean.carson@hyundai.com

Global PR Strategy & Planning · Hyundai Motor Company

Disclaimer: Hyundai Motor Group believes the information contained herein to be accurate at the time of release. However, the company may upload new or updated information if required and assumes that it is not liable for the accuracy of any information interpreted and used by the reader.

About Hyundai Motor Group

Hyundai Motor Group is a global enterprise that has created a value chain based on mobility, steel, and construction, as well as logistics, finance, IT, and service. With about 250,000 employees worldwide, the Group’s mobility brands include Hyundai, Kia, and Genesis. Armed with creative thinking, cooperative communication and the will to take on any challenges, we strive to create a better future for all.

More information about Hyundai Motor and its products can be found at:

http://www.hyundaimotorgroup.com or Newsroom: Media Hub by Hyundai , Kia Global Media Center (kianewscenter.com) , Genesis Global Newsroom